ERG ENGINEERING

More than just foam.

Our engineering team helps design and test your custom parts, and our in-house machine shop manufactures your design to final shape

GET STARTED NOWEvery step of the way

We offer support at every stage of the process, whether you’re ready for production or just getting started.

1

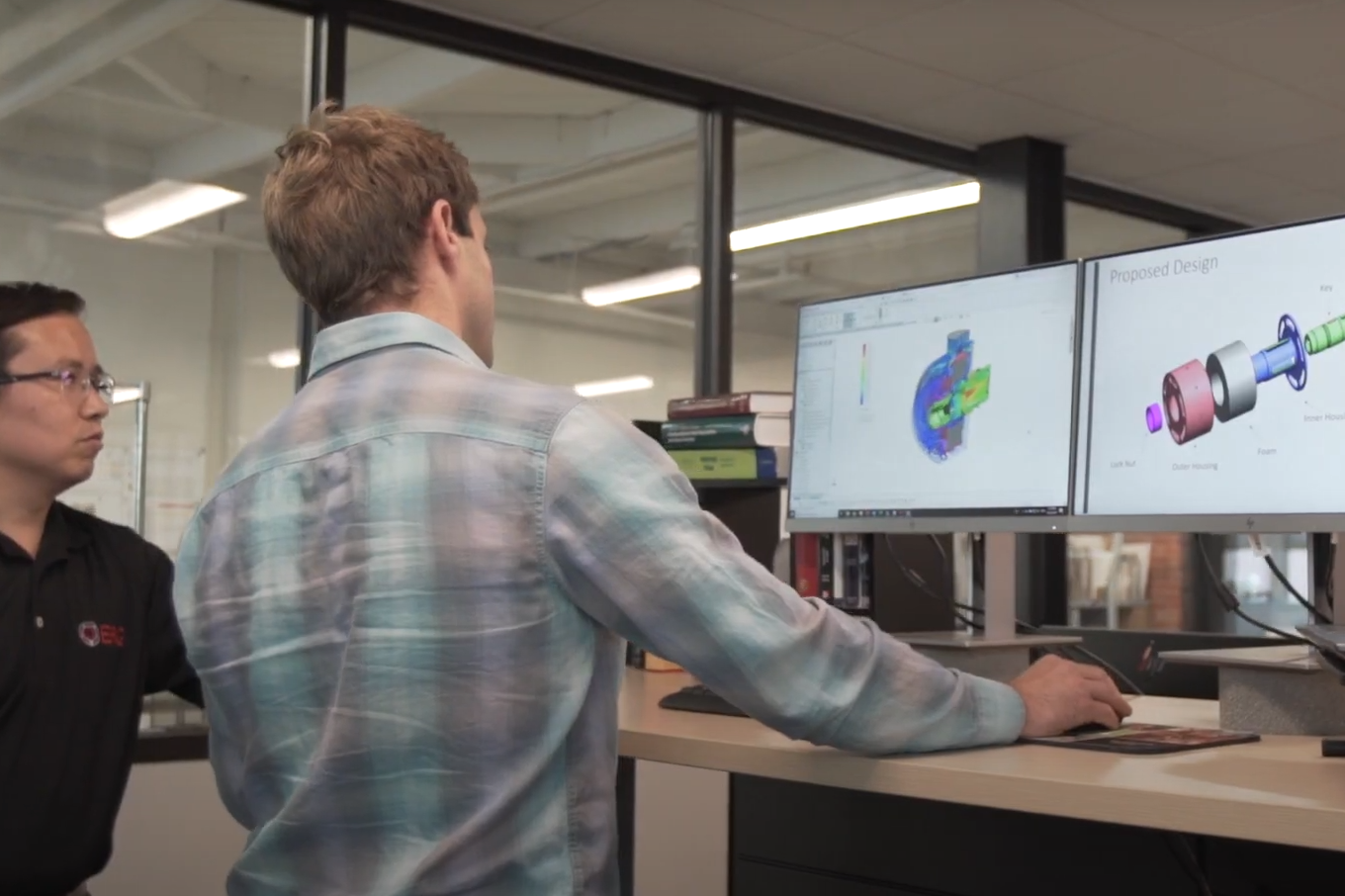

DESIGN

We’ll help you choose the best foam configuration, design for manufacturing, and make sure you’re using Duocel® to its fullest potential

2

ANALYSIS & TESTING

We do analysis through traditional FEA and CFD methods as well as our own foam-specific analysis, experimental testing, and qualification testing

3

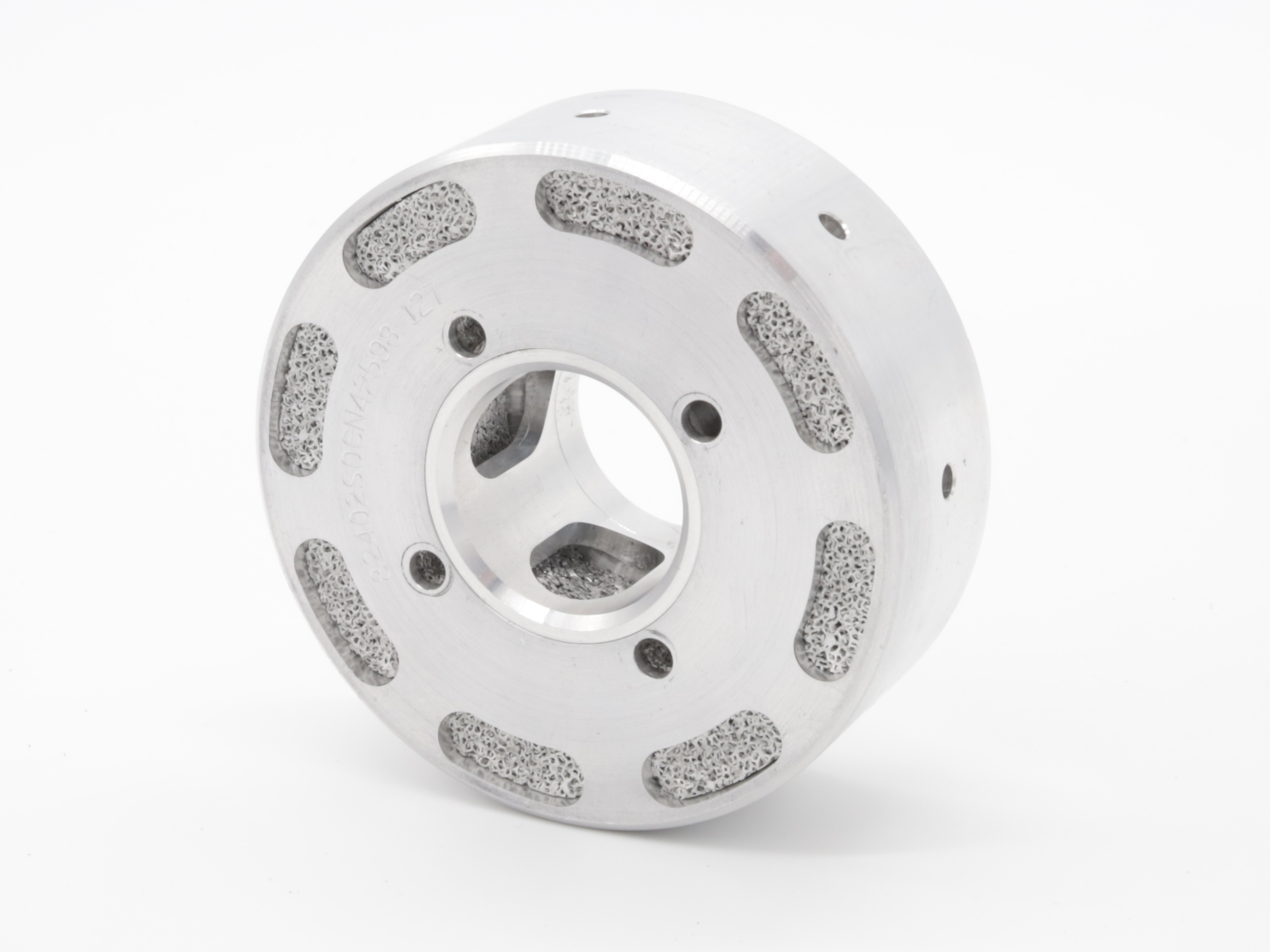

MANUFACTURING

Our expert in-house machinists and proven foam processing techniques ensure you receive the highest quality final parts

Talk to our engineering team!

CONTACT ERG AEROSPACETruly custom solutions.

CONFORMAL GEOMETRIES

Parts can be machined/formed into complex geometries so Duocel® fits perfectly into your system.

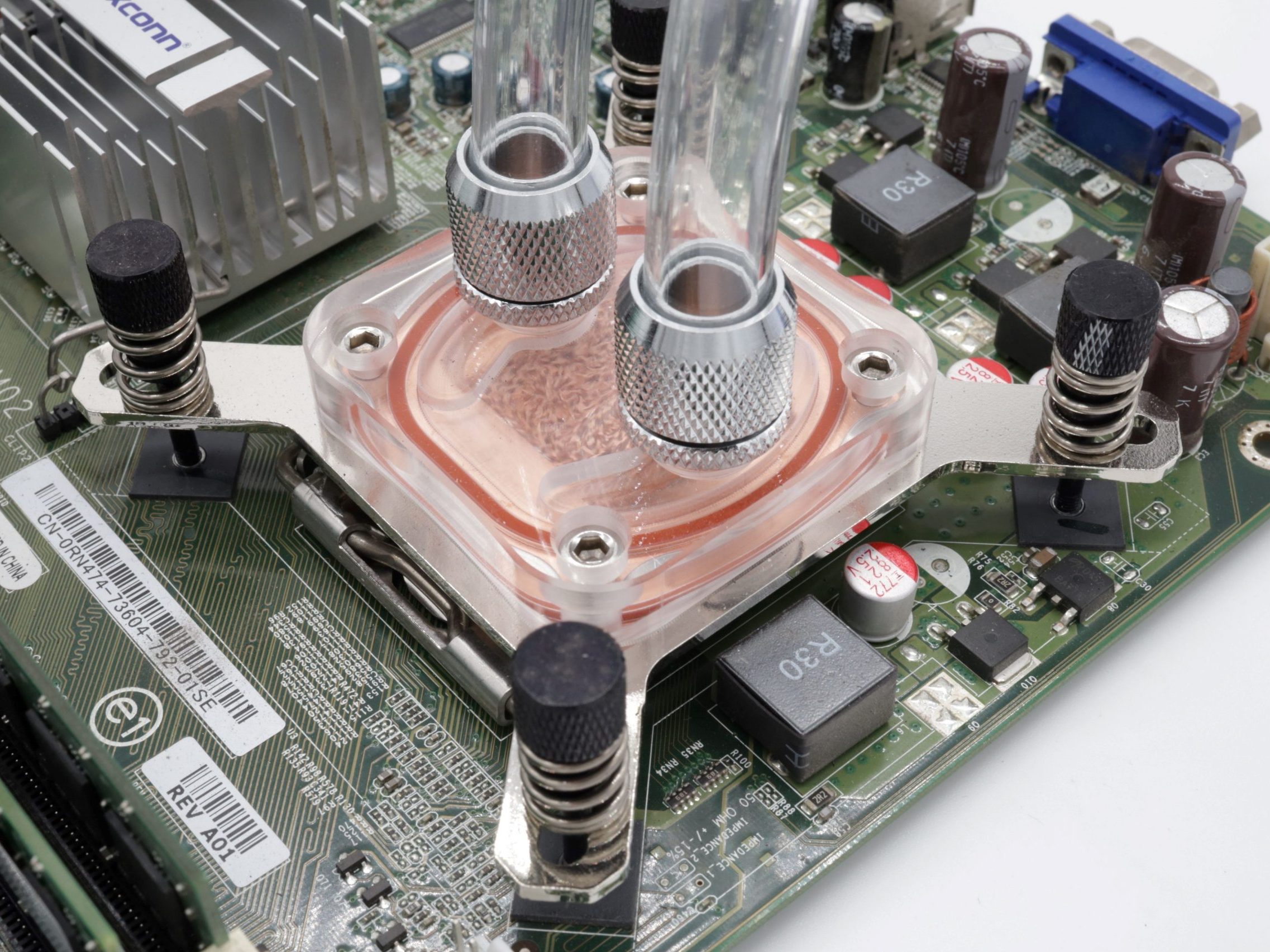

COMPLEX ASSEMBLIES

We can bond, braze, and solder Duocel® to get an excellent mechanical or thermal interface.

MATERIAL OPTIONS

Different metal alloys and heat treat conditions are available to achieve the properties you need.

SURFACE FINISHES

Duocel® can be chemical conversion coated, anodized, or plated for corrosion resistance, wear resistance, or electrical insulation.

THERMAL PROTECTION SYSTEMS

Duocel® Ceramic can be skinned to provide a smooth, easy to handle outer surface and impregnated with MAX Phase material to further increase working temperature.

FLEXIBLE PRODUCTION

Whether you have a one-off project or a full production run, we can meet your needs.